This article was originally published in AsphaltPro Magazine. See the full article HERE.

PlantDemand Delivers on Plant Requests

MARCH 8, 2021

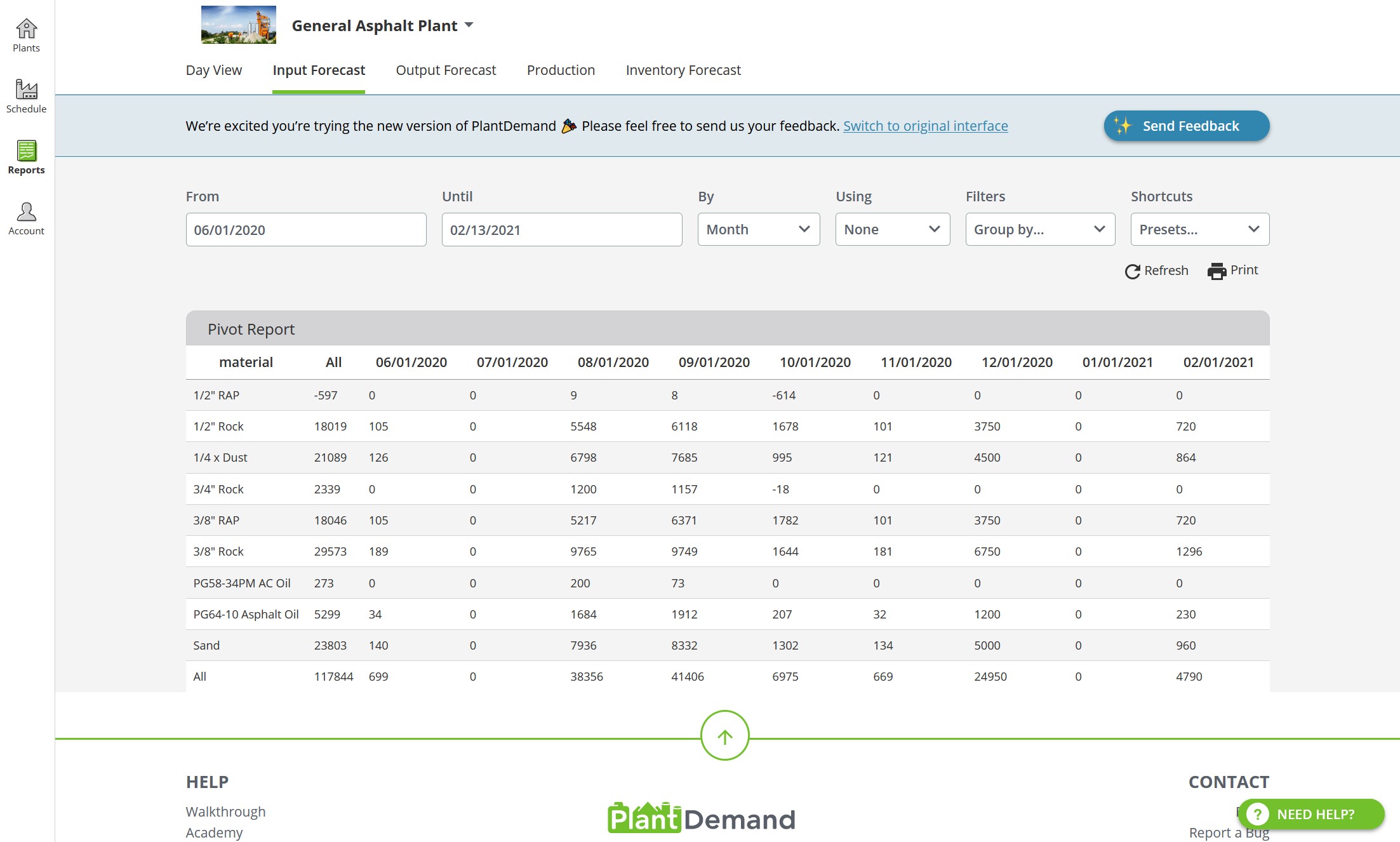

PlantDemand, Munich, Germany, was born when software developer Dennis Schaaf partnered with Daniel Mekis, an assistant plant manager at six asphalt plants and three quarries at the time, to develop a scheduling software. Mekis was spending hours every month generating materials reports and distributing this information to the facilities he managed and their suppliers.

“At the time, everyone used Excel, Outlook, phone calls, and notepads to assemble and share the plant schedules, but there were many problems with this due to not having up-to-date information between the team,” said PlantDemand Communications Lead Paulina Schaaf.

Dennis Schaaf began working with Mekis and his network of materials producers to better understand users and build a tool that would resolve these issues. In 2015, the plant scheduling software PlantDemand was born, and what used to take Mekis hours could be done in a few seconds.

In the ensuing half-decade, much has changed. The staff at PlantDemand has grown, and so has the software’s customer base. At launch, it was in use by a handful of plants; today, it’s in use by more than 1,000 users worldwide, 80 percent of which are located in North America. What has not changed is PlantDemand’s responsiveness to the needs of materials producers.

“[Dennis Schaaf] and the development and design team have continued to work closely with asphalt plant personnel using the tool, steadily releasing improvements to the software over time,” Paulina Schaaf said.

In 2020 alone, PlantDemand released a new design with a number of updates to assist its users. These updates include the ability to move orders from one plant to another, search orders, improvements to custom field and user management, as well as the launch of an API integration feature. API integration allows customers to integrate PlantDemand with other systems and data they may use, and create custom dashboards of company data.

“While there are many options when it comes to integration, a simple approach is to give people the ability to query their data, and let them configure it in a way that works best for their goal,” Paulina Schaaf said. “We aim to make every day tasks easier for the people involved.”

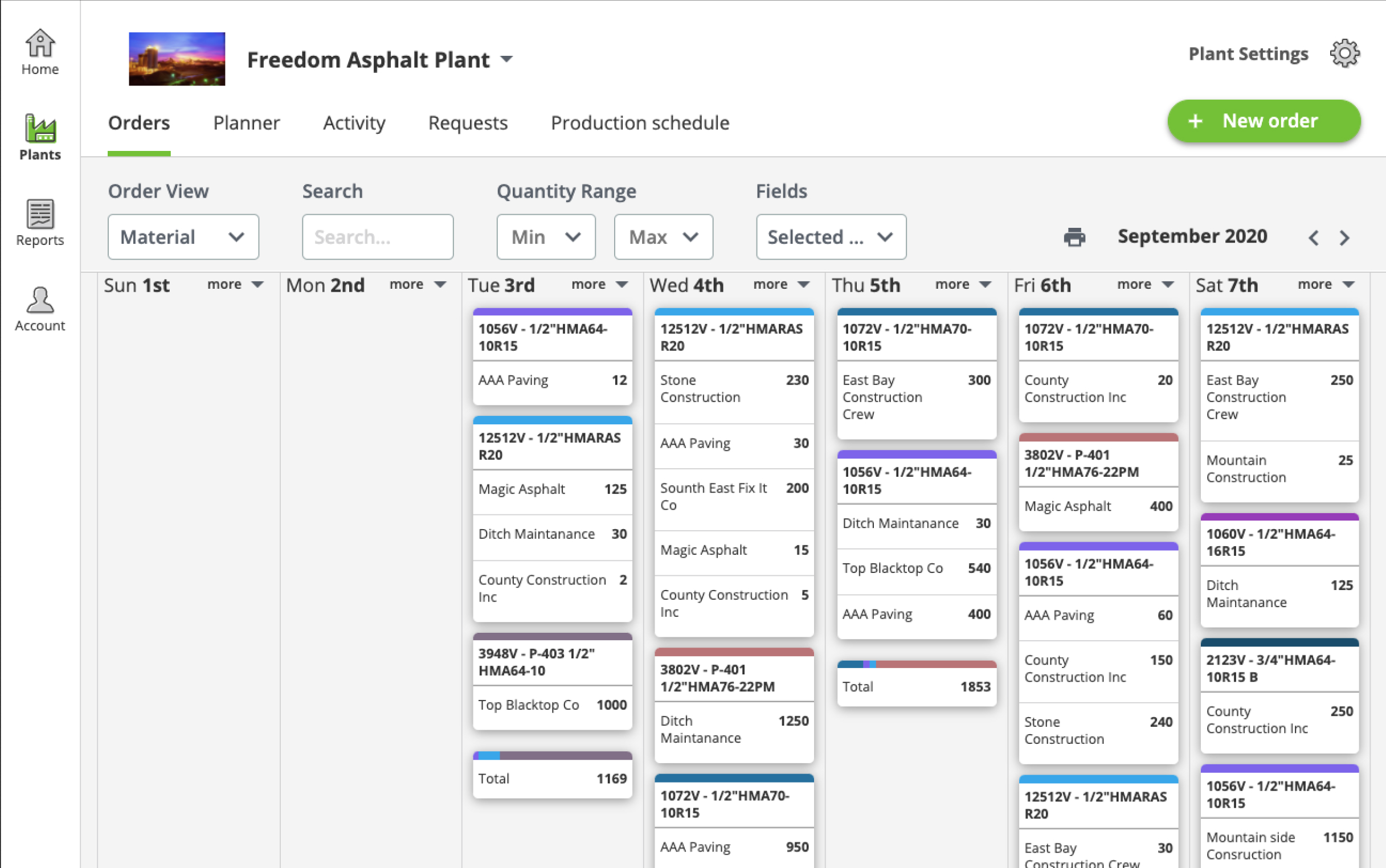

That has been true from day one. PlantDemand aims to improve collaboration between sales and production teams to enhance forecasting, reduce overbooking and run-outs of supplies, and improve daily materials and production planning. Its shared live calendar feature is designed to make it easy for the entire team to see everything in one place. Changes can be made and accessed in real time online or with the PlantDemand app, and order updates are saved in the update log.

“On average, an order is updated six times before it actually ships,” Paulina Schaaf said. “In the past, imagine the number of phone calls, emails and text messages that would be required to keep everyone in the loop.”

Dennis Schaaf shared a number of examples when an order listed the wrong AC supplier than the one indicated on the submittal for the project. PlantDemand made it easy to resolve the issue. “We’ve heard this exact case from others where several thousands of tons were shipped with the incorrect supplier,” Dennis Schaaf said. Ultimately, the plant was responsible for warranty of the mix for several years, he added, increasing potential risk to their business “to the tune of potentially millions of dollars.”

Back in the day, operations often held weekly scheduling meetings to discuss changes. Now, Dennis Schaaf said, those conversations “change from what is on the schedule to how they can plan to produce everything more efficiently.”

With plant scheduling software like PlantDemand, there is a single true source of information for plant operators, sales people, the quality control team, managers and engineers. This is made all the more true with PlantDemand’s new API integration.

As time goes on, PlantDemand remains committed to consistent improvements.

“We conducted user interface tests and interviews and in this way the software was iteratively built, tested and optimized for construction material planning,” Paulina Schaaf said. “It’s important that these tools are made for easy usage for the everyday busy lives of plant people.”

One Day With PlantDemand

The process to begin:

The night or afternoon before work, the plant operator schedules and sets the crew up for the proper start time. (Because it’s an online tool, they can even be doing this from the app or from their home office.)

When they arrive in the morning, they typically print out the Day View Report (a daily dispatch style report generated in PlantDemand with all order information for the day) and keep it on their desk for taking notes throughout the day.

They fire up the plant and begin to produce the mix based on the scheduled start times, quantity, etc., that the different customers requested.

They use the Day View report to find orders in the ticketing system and make sure that each customer is receiving the mix they requested. As the project foreman calls the plant operator or the dispatcher, the operator keeps notes for the current day’s operation. If the foreman notifies them of plans for the next day or coming days, the plant operator can add or edit an order in PlantDemand (which the sales team, managers, QC, etc., can all see, too).

As sales/dispatch talks with customers, they can also view the latest schedule for the plant and add/edit orders. The plant operator can see these changes and can communicate concerns with the team, if needed.

At the end of the day, typically, a sales person or dispatcher will go to the Day View Report, and click “Share with My Organization.” This generates an email notification of the report that is sent to all users of that plant. So, in case someone on the team hasn’t had a chance to view the calendar, they will see what is planned for the next day.

–This article was originally published in AsphaltPro Magazine and is reprinted here with permission from the author, Sarah Redohl. See the full article HERE.–